Ligature resistant, otherwise known as anti-ligature or behavioral health door hardware is designed to make it difficult for folks to use it for suicide by hanging or otherwise harming themselves or others. Pictured adjacent are cylindrical knob and lever locks by Marks USA and a mortise lock by TownSteel.

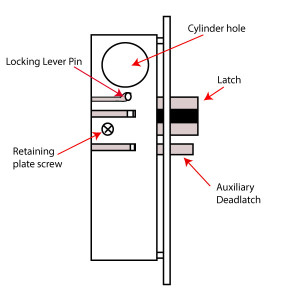

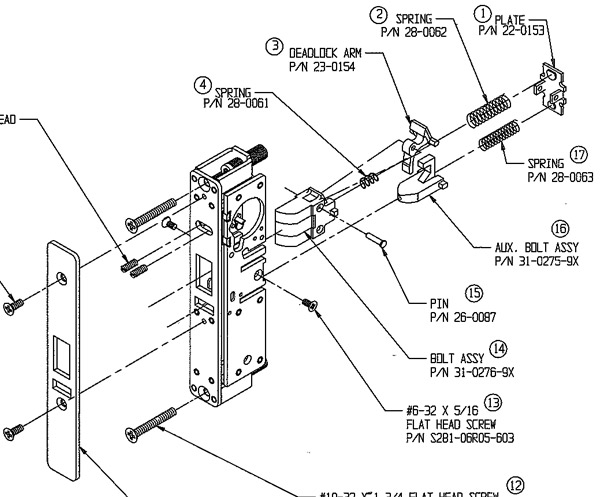

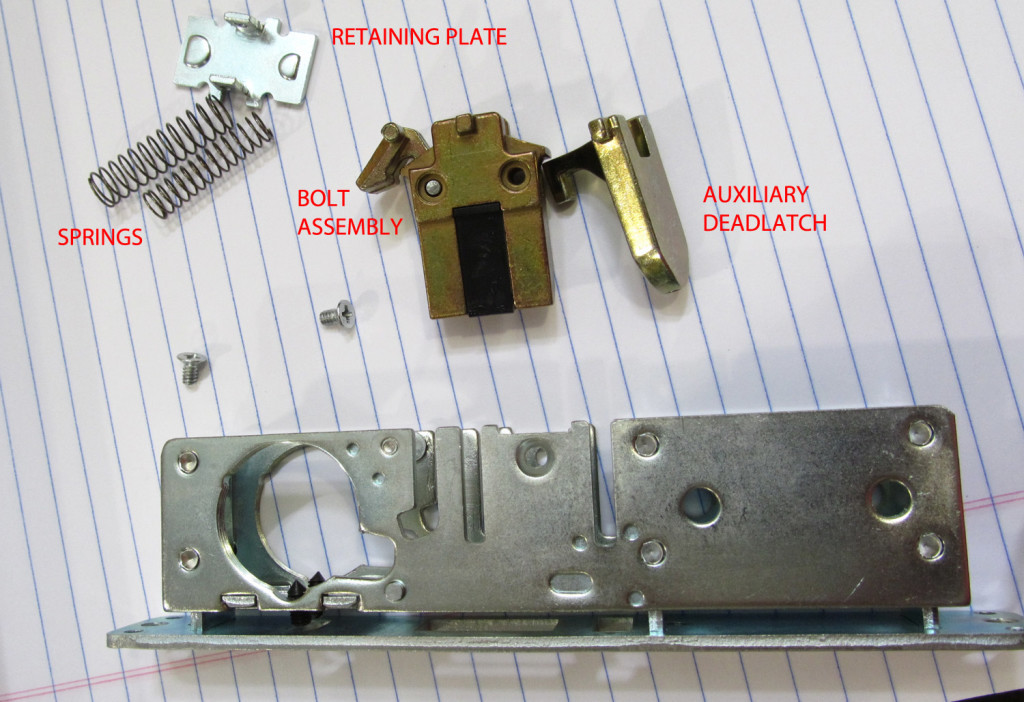

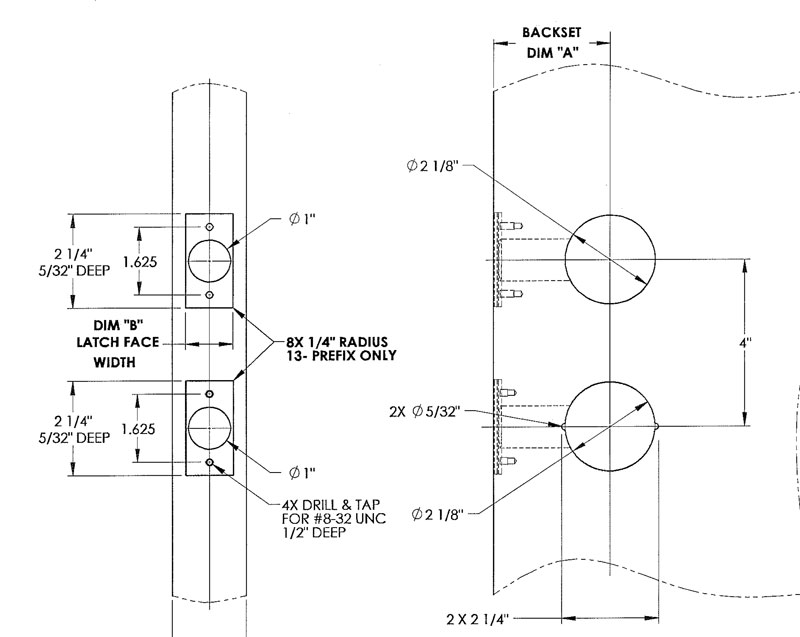

All are designed to resist attempts to hang oneself. The cylindrical lever and knob locks feature more or less conical designs that cause a cord to slide off of them regardless of how one might try to tie it on. The lever turns freely even when locked, achieving the same result. The mortise lock uses a conical cylinder collar and sloped trim to achieve ligature resistance. The opening in the pull is closed by a steel plate, making it impossible to pass a cord through it. The exposed fasteners are security fasteners that require a special tool to loosen, and they fit flat and flush to the escutcheon and lock front.

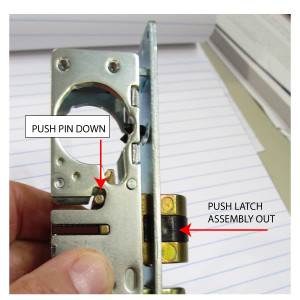

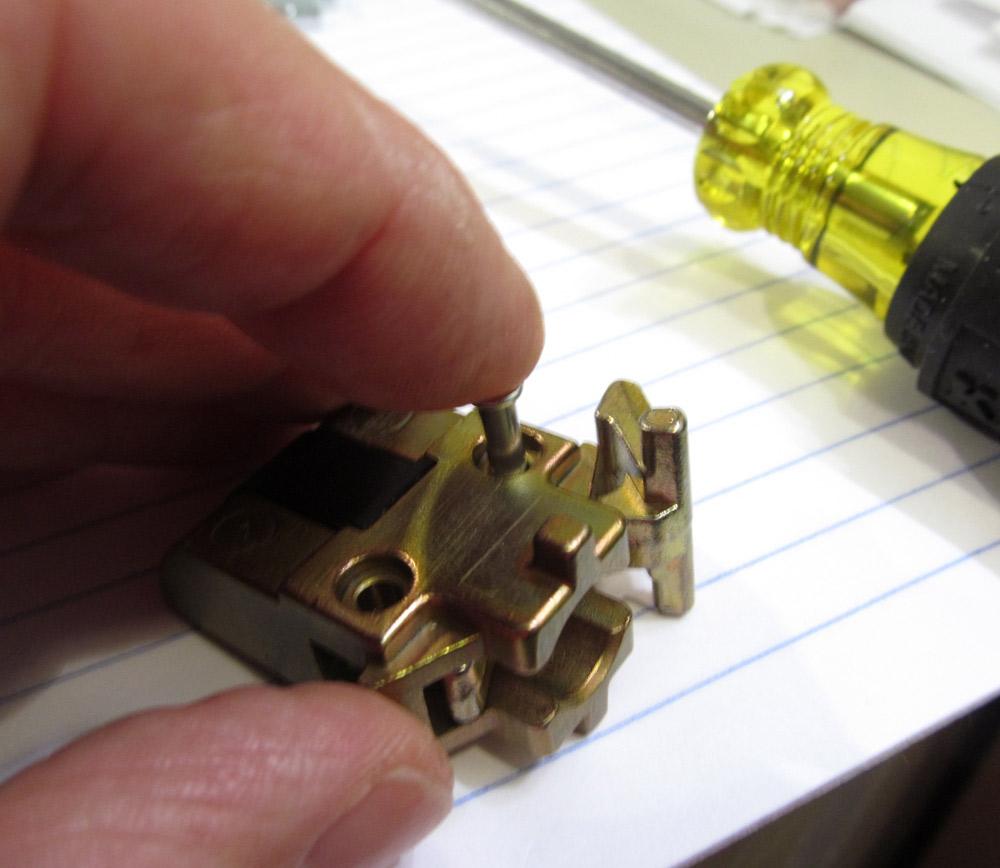

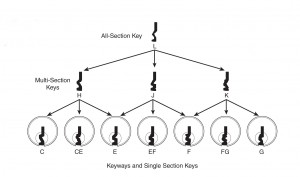

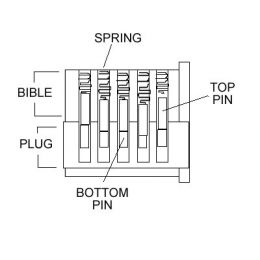

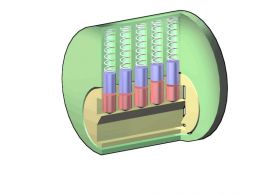

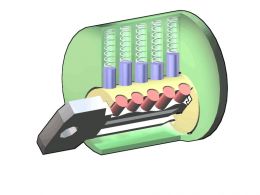

When you sell or install ligature resistant hardware it is best not to modify the product in any way, because in doing so you will assume all responsibility for anything that happens as a result involving the hardware. This can include disassembling a cylindrical lock to rekey it. For this reason I recommend that when keyed anti-ligature locks are specified they are specified as interchangeable or removable core locks.

When you sell or install ligature resistant hardware it is best not to modify the product in any way, because in doing so you will assume all responsibility for anything that happens as a result involving the hardware. This can include disassembling a cylindrical lock to rekey it. For this reason I recommend that when keyed anti-ligature locks are specified they are specified as interchangeable or removable core locks.

Ligature resistant hinges have hinge tips called “hospital tips” that are sloped to discourage suicide attempts (see McKinney hinge adjacent). Security screws also help keep folks safe by making it difficult to use the hinge to hurt oneself or others. Select Hinge offers a little gem called the “Tipit” for continuous hinges that makes continuous hinges ligature resistant.

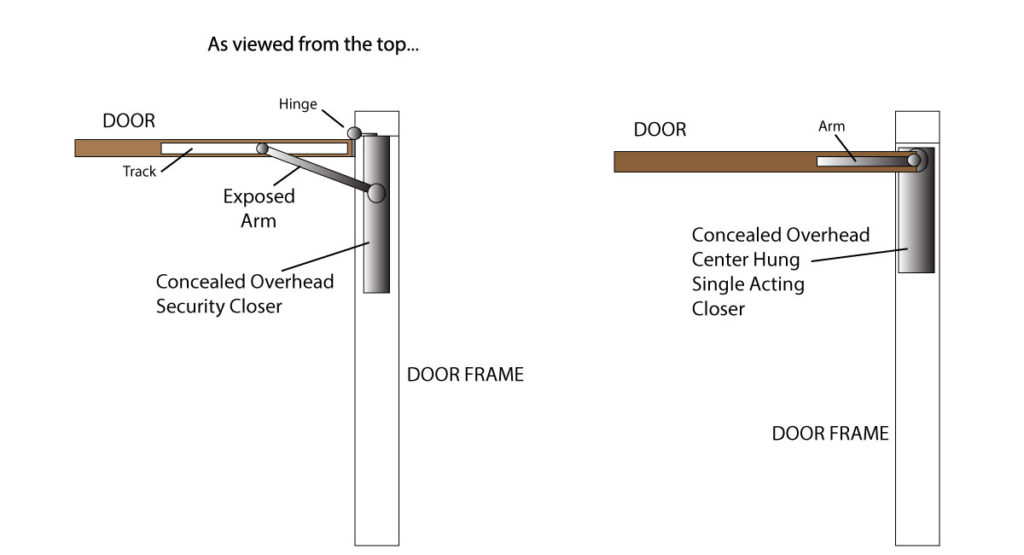

Increasingly I field inquiries for ligature resistant door closers for butt or offset hung doors, but to my knowledge there is no such animal as of this writing. Various factory tech support people have recommended overhead concealed security closers for ligature resistant applications, and this seems to be the consensus at this time.

Increasingly I field inquiries for ligature resistant door closers for butt or offset hung doors, but to my knowledge there is no such animal as of this writing. Various factory tech support people have recommended overhead concealed security closers for ligature resistant applications, and this seems to be the consensus at this time.

I believe that using doors that are center hung with single acting, concealed overhead or floor closers would be safer and would eliminate the need for anti-ligature hinges; but this is impractical for retrofit applications where butt or offset hung doors are already present in abundance.

In the illustration below I show why I feel a center hung, concealed, single acting door closer would be the best choice for ligature resistance.

In door hardware, safety is the most important consideration.

Your source for quality security products with superior service!