I have mentioned this before, but it bears revisiting. Lock problems and door problems are often related. If the door is does not swing or is not hung properly the lock may not work properly either.

I bring this up now because I was recently called upon to go out and do actual work. I am no longer used to this and will usually refuse these opportunities, but my daughter called to say that the restaurant where she is working was having problems with their walk-in wine cooler. This small, chilled room is unfortunately located near the entrance of the restaurant, around the corner from virtually all activity except exiting and entering. Should an unscrupulous patron give the grade one cylindrical storeroom function lock a tug on their way out, the door would swing open, inviting pilferage of some very expensive vintages ranging in the hundreds of dollars. Some might even qualify as grand theft. So she asked if I would come out and have a look, and being the wonderful dad I am I grabbed my toolbox and cordless drill and headed out.

I managed not to hurt myself, so I am grateful.

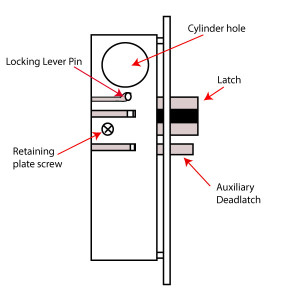

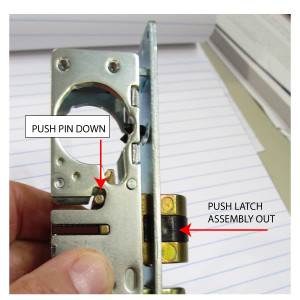

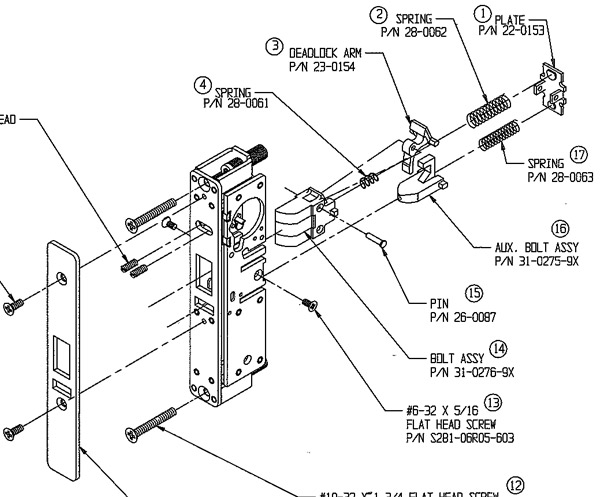

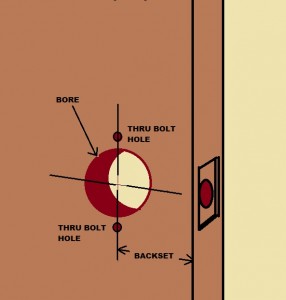

When I arrived on the scene, I noticed immediately that the door was sagging – that is to say, it was no longer square within the door frame. I could tell because – as in the handy picture I provided above – I could see that the gap between the header and the door was noticeably larger on the lock side than on the hinge side of the door. I checked the top hinge screws – often the culprit in these situations – but all was well up there and all the screws were tight. This could mean only one thing: the door frame had settled with the building and was no longer square. As a result the latch no longer lined up with the electric strike and the lock would no longer latch.

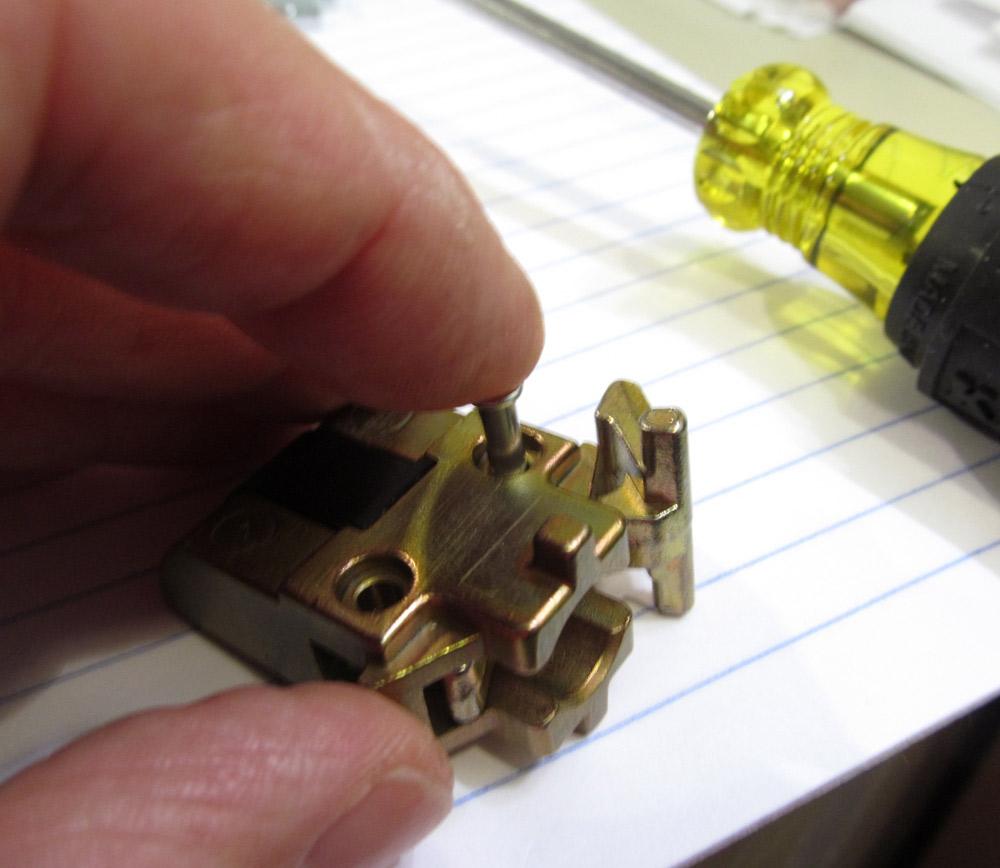

Since the door was wood I could have pulled the door, removed the hinges, planed the hinge edge and re-cut the top and middle hinge mortises to bring the lock edge up and back in line with the frame; or I could broken into the walls on both sides and adjusted the door frame so it would be square again. But because I am old, tired, and was not getting paid I decided to take the easy way out: I shimmed the bottom hinge, forcing the lock side of the door slightly up so that the lock would once again align with the electric strike.

Since the door was wood I could have pulled the door, removed the hinges, planed the hinge edge and re-cut the top and middle hinge mortises to bring the lock edge up and back in line with the frame; or I could broken into the walls on both sides and adjusted the door frame so it would be square again. But because I am old, tired, and was not getting paid I decided to take the easy way out: I shimmed the bottom hinge, forcing the lock side of the door slightly up so that the lock would once again align with the electric strike.

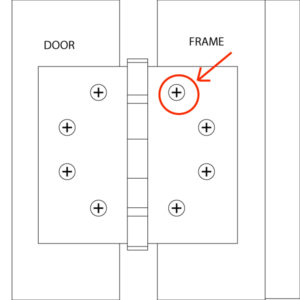

To shim the bottom hinge I simply put a washer behind the hinge at the location shown in the picture at right. Then I explained to the restaurant manager that this was a temporary fix and that later on the door would most likely need attention again because the problem would probably recur.

So I left everyone happy and with a working door, but also with a warning. Since the door frame is no longer square it is likely to continue in the same direction and someone (not me) will have to address it in the future.

And once again I looked like a … Hardware Genius.