To intelligently choose a door closer for your application you have to know certain facts:

- Does the closer need to comply with ADA opening force guidelines?

- Is the door an interior or exterior door?

- What is the door width?

- Will the closer be mounted on the push or pull side of the door?

- Where on the door will the door closer be installed? How much room is there?

- Are there any special circumstances like wind, positive or negative pressure, etc.?

- You may also need to know the door handing.

ADA Reduced Opening Force Guidelines

American Disabilities Act (ADA) reduced opening force restrictions are enforced by the Authority Having Jurisdiction in your locality. In some localities or applications ADA requires a maximum opening force of 5 lbs. and in others a maximum opening force of 8.5 lbs. Most closers on the market today can be field adjusted to comply with these restrictions, but to do so you need to have a door pressure gauge.

I am mildly acquainted with two door pressure gauges. One is the model DPG by HMC and the other is the ADA/FG by LCN. Apparently there are a lot of initials involved in door pressure.

Door closers are also available with reduced opening force meant specifically to comply to ADA standards.

Manufacturers usually print a disclaimer that says that a door closer adjusted to ADA maximum opening force may not have enough power to shut the door. This is often true because perhaps recommended spring strengths for different applications are the result of perhaps a century of innovation. Manufacturers know that a force greater than 8.5 pounds may be necessary to close a door.

Interior versus Exterior

When speaking about door closer closing force, we say that a door closer is of a certain size. Door closer size does not refer to actual dimensions, but to spring strength. Historically, door closers are available in sizes 1 through 6 – 1 being the wimpiest and 6 capable of exerting the strongest closing force.

A size 4 closer is usually recommended for an exterior, 3-foot wide door, whereas a size 3 closer is deemed appropriate for an interior door of the same dimensions. The assumption here is that the exterior door is more likely to be expected to close a door against a wind or negative or positive air pressure.

Door Width

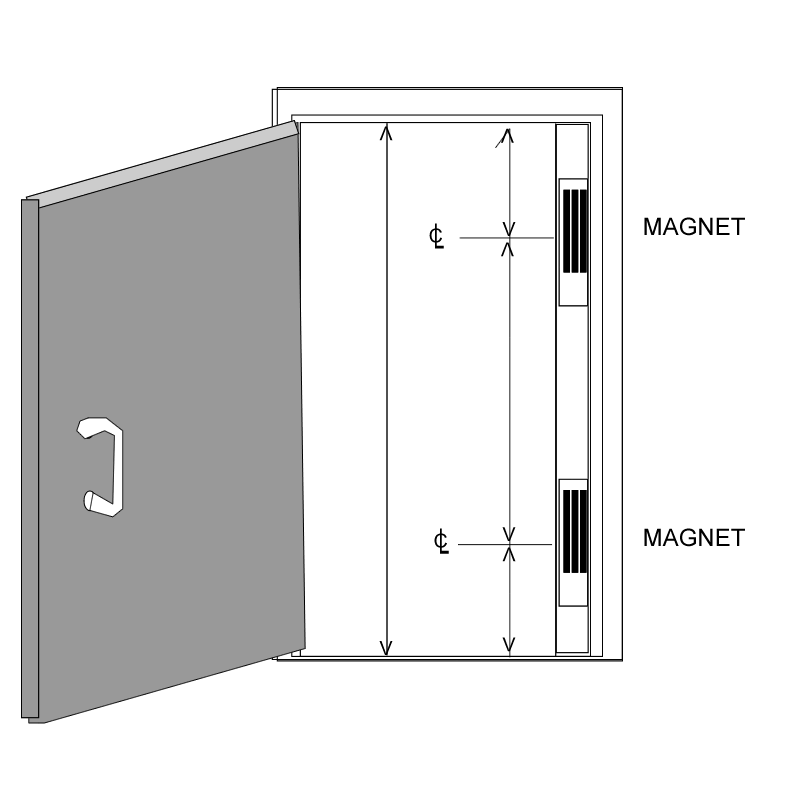

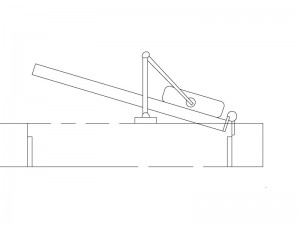

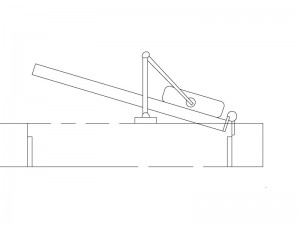

If you look at a door hung on butt hinges and equipped with a door closer from above, it looks something like this:

View from the Ceiling

You see from the illustration that the door closer closes the door by exerting force on a point about eight or ten inches from the hinge side of the door. To see what this means, go to a door with no door closer. Open it. Now put your hand a foot from the hinge side of the door and push it closed. Pretty difficult, isn’t it? If your door was wider, it would be even harder to close from that point. This is why door closer size – that is, spring strength – is determined by the width of the door rather than the height.

For a three foot wide exterior door, you would normally adjust your door closer to be a size four. For a four foot wide exterior door you would adjust your door closer to be a size five. Therefore, if you have a four foot wide exterior door, you had better buy a closer that can be adjusted to a size five.

Push or Pull?

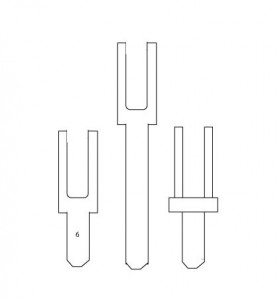

Different arms are required for different applications. On doors that swing out, where the closer is mounted on the push side, the closer is mounted in a top jamb or parallel arm configuration. If it is mounted on the pull side it is mounted in what is called a ‘standard’ installation. (There are other ways to mount a closer on the push side, but parallel arm and top jamb are the most common.)

See manufacturer’s literature for more information, or check out my article on Door Closer Basics.

Room

If you have a glass and aluminum storefront kind of door, you may have a space issue as regards your choice of door closer. If you have a hollow metal door with no window hung in a steel frame, chances are you will have no space issue.

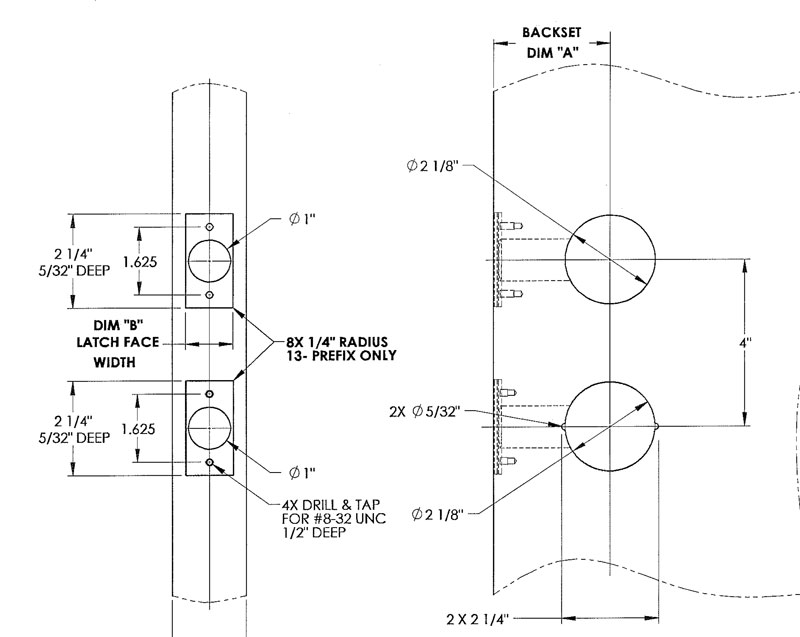

You need to figure out what door closer will fit. To do that, measure the space where you would like to install it and download installation templates or instructions from manufacturer’s web sites. Check the dimensions to see if the closer you have selected will work or not.

Or you can measure your door and frame and consult a door hardware professional.

Special Circumstances

I have installed door closers in some fairly challenging environments. One, for example, was on a four foot wide, eight foot high, two and a quarter inch thick mahogany and glass door. In addition to the size of the door, the location was also challenging – right across Beacon Street from the Boston Common where the wind could race across the open ground and dash itself against the door to its heart’s content. Also, the front of the building had settled over the century or so of its existence, and leaned decidedly inward. The door opened inward, and, left on its own, would swing sedately inward to 90 degrees if not latched.

In other words I had to install a door closer that would close an extra heavy door, uphill, in a wind. I actually got one that would do it about 95% of the time. For this application I chose the most durable, powerful, adjustable door closer I knew at the time: the LCN 4041. If I did the same job today I would probably choose an LCN 4011 or a Norton 7500.

A big, beefy, versatile door closer is not a cure-all. For example, sometimes the 4041 is just too big, or templated too close to the hinge. The point is that you must look at all the details of your door before you buy a door closer – not only how it is made and its size, but its environment as well.

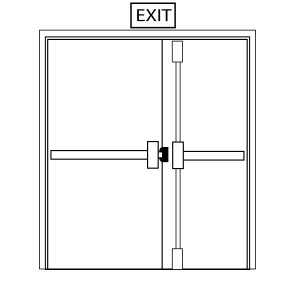

One of the hallmarks of bad hardware choices is the “pocket ripper” strike, used on a pair of doors when there is an inactive leaf with flush bolts or a vertical rod exit device and an active leaf with a rim exit device. Whenever I see this I think, “Cheap bastard,” because the only reason for this half fast solution is money and the desire not to spend it on doing the job right.

One of the hallmarks of bad hardware choices is the “pocket ripper” strike, used on a pair of doors when there is an inactive leaf with flush bolts or a vertical rod exit device and an active leaf with a rim exit device. Whenever I see this I think, “Cheap bastard,” because the only reason for this half fast solution is money and the desire not to spend it on doing the job right.